Stainless steel is one of the most versatile materials used in modern industry, with various surface finishes tailored for different applications. Among these, the bright annealed stainless steel tube stands out due to its high-gloss, smooth surface, superior corrosion resistance, and excellent mechanical properties. It’s widely used in fields that require both performance and aesthetics—such as pharmaceuticals, food processing, architecture, and precision instrumentation.

In this article, we’ll dive deep into what bright annealed stainless steel tube really is, how it’s produced, what standards it must meet, how it differs from other finishes, and why it’s favored by so many industries.

Bright annealing is a heat treatment process performed in a controlled atmosphere—typically under a mixture of hydrogen and nitrogen—to prevent oxidation. Unlike traditional annealing, which can leave a dull or oxidized surface, bright annealing keeps the metal surface clean and shiny by eliminating oxygen from the environment.

A bright annealed stainless steel tube is made by cold-working the stainless steel and then heating it to high temperatures (typically 1040–1150°C) in a specially controlled environment. As the tube is cooled down in the same atmosphere, it retains a bright, reflective finish and a smooth, scale-free surface.

The result is a tube with a high level of dimensional accuracy, excellent corrosion resistance, and an aesthetically pleasing appearance—ideal for sanitary, food-grade, and decorative applications.

The most popular material for bright annealing, stainless steel benefits greatly from this process. A bright annealed stainless steel tube retains a smooth, reflective surface ideal for sanitary, food-grade, and high-precision applications. Common grades include:

Aluminum can also be bright annealed to restore ductility and reduce stress. While it doesn’t retain the same level of mirror finish as stainless steel, bright annealed aluminum is widely used in aerospace, automotive, and packaging industries.

Bright annealed copper is especially valued in electrical and plumbing systems. The process removes oxidation, preserves conductivity, and results in a clean, reddish shine. It is commonly used in HVAC, power distribution, and refrigeration.

Brass, an alloy of copper and zinc, can be bright annealed to improve its formability and surface finish. Bright annealed brass tubes are used in musical instruments, decorative items, and low-pressure fittings.

Nickel and nickel-based alloys are also candidates for bright annealing, especially in high-temperature and corrosive environments. These are used in the chemical processing, energy, and aerospace industries.

Annealing is a critical process in metal manufacturing. It involves heating the metal to a specific temperature and then cooling it down to alter its physical and sometimes chemical properties. The main reasons for annealing are:

Without annealing, stainless steel tubes could become brittle or suffer from reduced corrosion resistance. In contrast, bright annealed stainless steel tube undergoes a process that not only improves its structural properties but also enhances its surface quality.

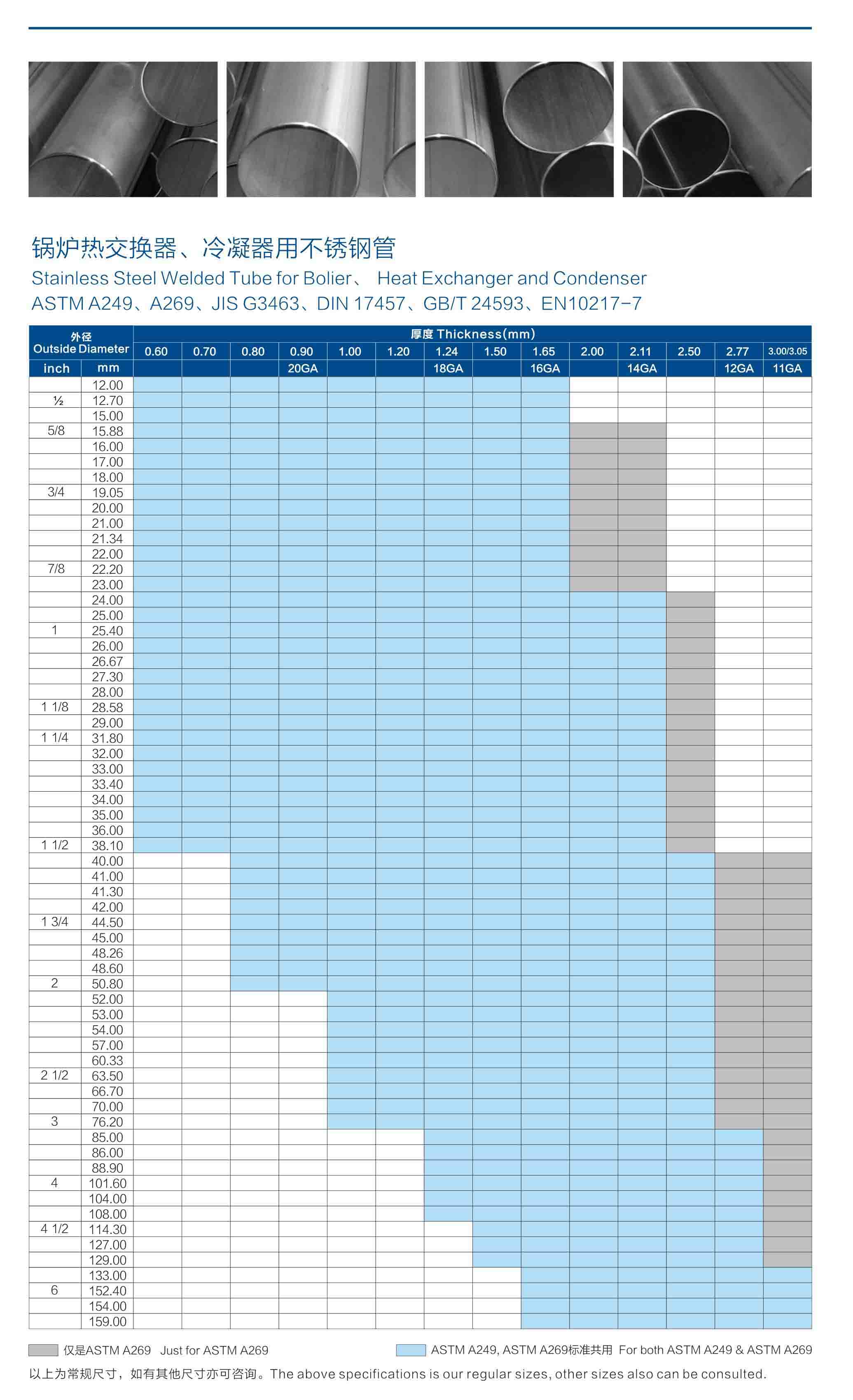

When producing bright annealed stainless steel tube, manufacturers often follow international standards such as ASTM A269 and ASTM A249. These standards ensure that the tubes meet specific requirements for dimensions, tolerances, mechanical properties, and corrosion resistance.

Each of these grades can be bright annealed, depending on the desired corrosion resistance, mechanical strength, and application environment.

Bright annealed stainless steel tube is available in a wide range of diameters and wall thicknesses. Typical sizes include:

Customized sizes are also available based on client requirements.

Read More: A Comprehensive Guide to Stainless Steel Pipe Dimensions Chart

Standard lengths are typically 6 meters, but tubes can also be supplied in custom-cut lengths upon request.

| Nominal OD (mm) | Tolerance (± mm) |

|---|---|

| ≤ 25.4 mm (1") | ± 0.10 mm |

| > 25.4 to 38.1 mm | ± 0.15 mm |

| > 38.1 to 50.8 mm | ± 0.20 mm |

| > 50.8 mm | ± 0.25 mm |

| Specification | Wall Thickness Tolerance |

|---|---|

| A249 | -0% / +20% (unless otherwise specified) |

| A269 | ± 10% standard (unless tighter control is requested) |

| Tube Length | Tolerance |

|---|---|

| Random Length | +50 mm / -0 mm |

| Fixed Cut Length | ± 3.2 mm (±1/8") typical |

Bright annealed stainless steel tube is used in:

Tubes are typically packaged in:

Only after passing these inspections can the bright annealed stainless steel tube be approved for shipment.

Besides bright annealing, stainless steel can be finished in several other ways depending on the application.

Produced by hot rolling followed by annealing and pickling. It’s rough and dull, used mostly in industrial settings.

Cold-rolled, annealed, and pickled with a dull surface. Slightly smoother than #1D but still used in non-decorative applications.

Cold-rolled and lightly polished. This is the most common mill finish, offering a smooth surface suitable for most general applications.

Learn More:

Unveiling the Versatility of 201 2B Stainless Steel

A coarser polished finish with visible grit lines. Often used in architectural panels or kitchen equipment.

A finer polish than #3, commonly seen in elevator doors, kitchen appliances, and other semi-decorative applications.

A highly reflective surface achieved through mechanical polishing. It’s very aesthetic but labor-intensive and expensive.

Compared to all these, bright annealed stainless steel tube delivers a clean, glossy finish directly from the furnace—making it more efficient and consistent for many applications.

You may also like: Best Stainless Steel Surface Finishes – A Complete Guide

Ordinary annealing is done in open air or in non-inert environments. Oxygen reacts with the metal at high temperatures, creating an oxidized or discolored layer. That’s why traditional annealing leads to dull surfaces requiring pickling or polishing afterward.

Because bright annealing is done in a high-purity hydrogen or nitrogen atmosphere, it prevents oxidation. The bright annealed stainless steel tube exits the annealing furnace with a naturally glossy and clean surface that doesn't need any additional finishing.

It can—but it’s not efficient. Polishing is labor-intensive, costly, and not always uniform. In contrast, bright annealed stainless steel tube comes with a consistent, high-quality finish right from the furnace. This reduces production time and cost, especially for high-volume or hygienic applications.

It depends on the application:

Among these, bright annealed stainless steel tube offers a great balance between aesthetics, cleanliness, and efficiency—making it one of the most useful finishes in many industries.

From pharmaceuticals to architecture, the bright annealed stainless steel tube has proven to be a versatile, high-performance solution. Its unique manufacturing process delivers unmatched cleanliness, corrosion resistance, and dimensional precision. Whether you’re looking for a hygienic solution for food processing or a sleek tube for decorative applications, this product stands out as a reliable choice.

With adherence to international standards like ASTM A269 and A249, and options available in 304, 316, 201, and 430 grades, bright annealed stainless steel tube is engineered to perform in the most demanding environments. Its popularity continues to grow among engineers, designers, and procurement professionals who need quality without compromise.

If you are sourcing high-quality stainless steel tubes, choose bright annealed stainless steel tube for a finish that shines—literally and functionally.