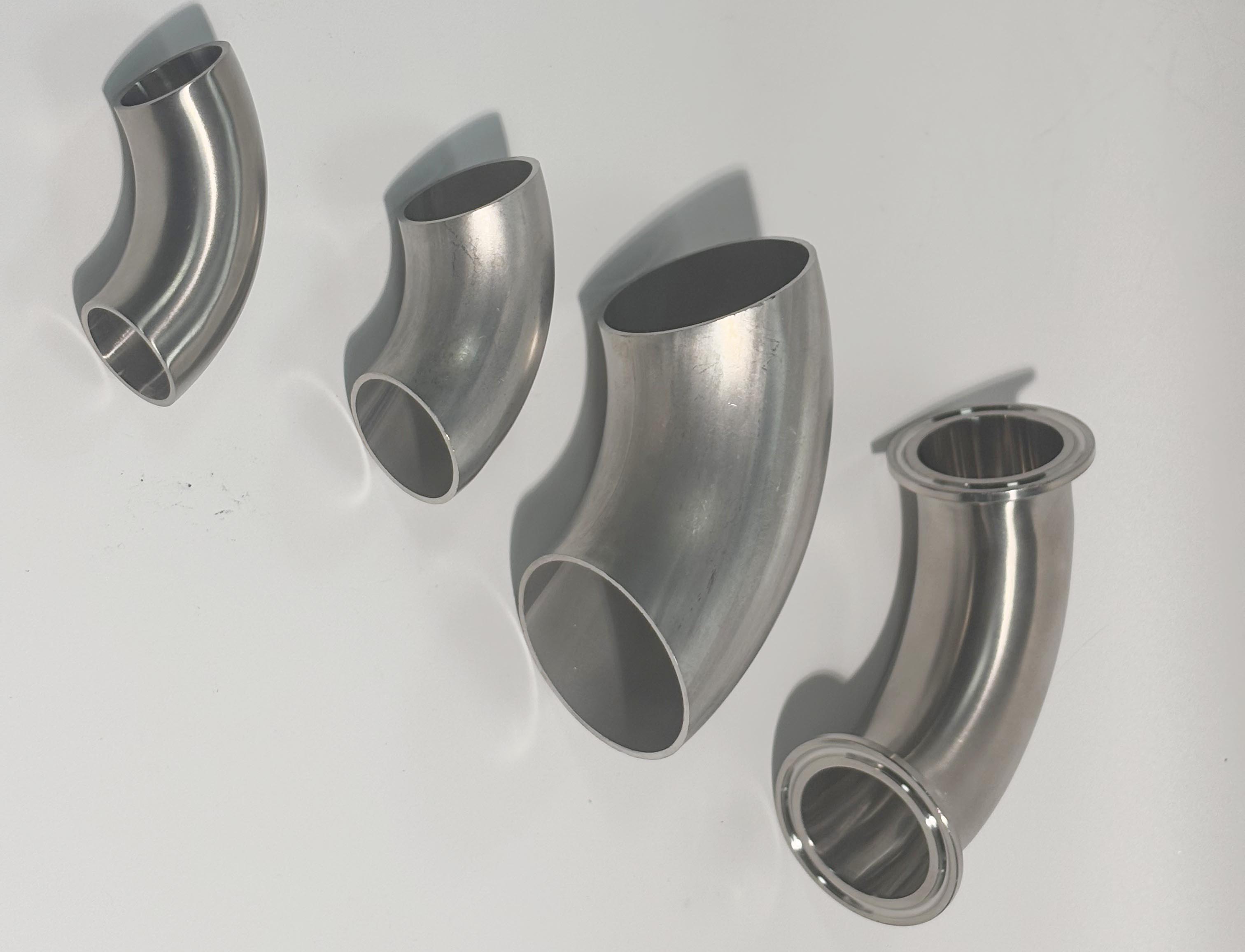

Sanitary elbows are critical components in hygienic pipeline systems used across food processing, beverage production, dairy plants, pharmaceuticals, biotechnology, and cosmetic manufacturing. These industries require fittings that ensure clean fluid transfer, reliable corrosion resistance, effective sterilization, and strict compliance with sanitary standards. As a leading global manufacturer of stainless steel welded tubes and hygienic fittings, Vinmay provides high-precision sanitary elbows designed for sanitary processing environments where product purity and equipment integrity are essential.

This comprehensive technical guide presents an in-depth understanding of what sanitary elbows are, how they are measured, how they are classified, and how they compare with industrial pipe elbows used in non-sanitary applications. The article also explains why sanitary elbows must be manufactured with high-purity stainless steels and mirror-polished internal surfaces to meet the requirements of modern hygienic industries.

A sanitary elbow is a curved stainless steel fitting installed in hygienic pipelines to change the direction of product flow. Unlike ordinary industrial elbows, sanitary elbows are manufactured from stainless steel 304 or 316L, materials selected for their superior corrosion resistance, ease of cleaning, and compatibility with CIP (Cleaning-in-Place) and SIP (Sterilization-in-Place) processes.

These elbows ensure directional changes without creating areas where residues can accumulate. For this reason, sanitary elbows are indispensable in hygienic processing lines requiring precise fluid control and unrestricted cleanliness.

The two primary grades selected for sanitary elbows are:

AISI 304 Stainless Steel - General-purpose stainless steel - Good corrosion resistance - Suitable for low-chloride environments - Common in food, beverage, and water processing

AISI 316L Stainless Steel - Contains molybdenum for enhanced corrosion resistance - Superior performance in chloride-rich environments - Preferred for high-purity pharmaceutical and biotech processes - Provides higher pitting and crevice corrosion resistance

Both grades allow sanitary elbows to withstand frequent cleaning cycles, high-temperature sterilization, and chemical exposure while maintaining structural stability and hygienic integrity.

Sanitary elbows are measured based on two key parameters: outside diameter (OD) and degree of bend. These measurements ensure compatibility with pipes, valves, and other sanitary fittings in a hygienic pipeline system.

OD is the most fundamental measurement in sanitary equipment, as the sanitary industry does not typically use nominal pipe size (NPS). Common OD ranges include:

1/2 inch to 12 inches

Custom OD sizes for specific sanitary systems

Metric sizes used in DIN and ISO standards

Imperial sizes used in 3A and SMS systems

Sanitary elbows must match the OD of the connecting pipe to form a leak-free and sanitary-safe pipeline.

The degree of bend determines the direction and angle at which fluid flow will change. The most commonly produced sanitary elbows are:

45° sanitary elbows for slight redirection

90° sanitary elbows for standard directional changes

180° sanitary elbows for return or loop lines

Custom angles (30°, 60°, etc.) are also manufactured for specialized hygienic processing layouts.

Accurate measurement and specification of these parameters help engineers design efficient and contamination-free processing pipelines.

Sanitary elbows are classified according to connection type, length, and bend radius. Understanding these classifications helps engineers select the correct elbow for flow requirements, installation space, and sanitary conditions.

Welded Sanitary Elbow - Most widely used connection in hygienic processing - Provides strong, permanent joints - Suitable for high-temperature systems - Eliminates dead angles where bacteria may accumulate - Requires professional welding and polishing

Threaded Sanitary Elbow - Features male or female threads - Used in low-pressure or temporary sanitary lines - Simple installation but not ideal for sterile systems - Requires accurate thread matching to avoid leaks

Flanged Sanitary Elbow - Uses flanges for easy assembly and disassembly - Suitable for equipment requiring frequent maintenance - Common in pharmaceutical and chemical pipelines - Ensures strong mechanical connection with gasket sealing

Short Radius Sanitary Elbow (SR) - Compact and space-efficient - Produces a sharper directional change - Higher flow resistance compared to LR elbows - Used where installation space is limited

Long Radius Sanitary Elbow (LR) - Larger curvature for smoother flow transitions - Less turbulence and lower pressure drops - Preferred for high-flow sanitary applications - Reduces product shear in sensitive fluid systems

LR sanitary elbows are generally preferred in food, dairy, beer, and pharmaceutical applications due to their superior flow characteristics.

Sanitary elbows may be classified as:

Short Radius (1D)

Long Radius (1.5D)

Custom radius (2D, 3D, or engineered specifications)

These values represent the centerline radius relative to the pipe diameter. Larger radii produce gentler flow transitions, essential for shear-sensitive or viscous products such as yogurt, creams, syrups, and pharmaceutical solutions.

Sanitary elbows are used in any processing system where fluid cleanliness is mandatory. Applications include:

Food Industry - Sauces, condiments, soups - Edible oils and fats - Canning and packaging systems - CIP circulation lines

Dairy Industry - Milk pasteurization - Cheese and yogurt processing - Cream and butter production - Sterile filling systems

Beverage and Brewery Processing - Beer brewing and fermentation - Wine and spirits production - Beverage bottling lines - Carbonated drink systems

Pharmaceutical & Biotechnology - Purified water systems - WFI (Water for Injection) pipelines - Injectable drug production - Fermentation and bioreactor systems

Cosmetics & Personal Care - Lotions, creams, gels - Perfume manufacturing - Sterile filling lines

Water & Chemical Processing - RO (Reverse Osmosis) systems - High-purity water lines - Mild chemical transfer systems

Across all these industries, sanitary elbows function not only as directional connectors but also as essential components for maintaining flow integrity, process hygiene, and equipment longevity.

Feature | Sanitary Elbows | Industrial Pipe Elbows |

Material | Stainless steel 304/316L | Carbon steel, iron, alloy |

Surface Finish | Mirror-polished (Ra ≤ 0.8 μm) | Rough, unpolished |

Hygiene Level | High | Low |

Corrosion Resistance | Excellent | Moderate to low |

Cleaning Compatibility | CIP/SIP safe | Not suitable for CIP |

Internal Smoothness | Prevents residue and bacterial adhesion | Causes turbulence and buildup |

Certification | 3A, DIN, SMS, ISO | Industrial standards |

Sanitary elbows are engineered to meet hygienic production requirements, whereas industrial elbows prioritize mechanical strength and cost.

Vinmay is a globally recognized manufacturer specializing in stainless steel welded tubes and sanitary fittings. Our sanitary elbows are designed and produced to meet international hygienic standards and demanding process conditions.

High-purity 304/316L stainless steel - Smooth internal polishing (Ra 0.4–0.8 μm) - Accurate OD and angular tolerances - High corrosion resistance - Compatibility with DIN, SMS, 3A, BS, ISO - CIP and SIP suitable

Material traceability Weld quality testing - Surface finish verification - Dimensional accuracy control - Pressure and sealing tests

Industry Applications - Food and dairy processing - Breweries and beverages - Pharmaceuticals and biotech - Cosmetics and personal care - Water purification facilities

Sanitary elbows are indispensable components in hygienic processing systems, providing smooth directional changes while maintaining the highest levels of cleanliness and corrosion resistance. Understanding their measurement, classification, applications, and differences from industrial pipe elbows helps engineers and procurement teams select the correct components for each processing environment.

While many types of industrial elbows exist—such as malleable iron elbows, pressed elbows, welded elbows, and high-pressure elbows—none of them can match the hygienic performance and internal finish required for food, beverage, dairy, pharmaceutical, and cosmetic manufacturing. Therefore, stainless steel sanitary elbows remain the standard for applications demanding product purity, hygienic design, and long-term reliability.

Vinmay continues to supply high-quality stainless steel sanitary elbows and sanitary fittings worldwide, supporting manufacturers in building safe, clean, and efficient fluid processing systems.