When it comes to stainless steel tube materials used in industries that demand superior corrosion resistance and durability, 316 stainless steel stands out as a top choice. Whether you are working on marine applications, food processing, pharmaceuticals, or any other sector that requires high-performance materials, 316 stainless steel tubes offer unparalleled advantages. This alloy's composition, which includes molybdenum, provides exceptional resistance to corrosion, even in harsh environments like saltwater and chemicals.

The quality, service, and experience of your 316 stainless steel tube supplier play a key role in determining the success of your project. In this guide, we’ll walk you through the essential factors to consider when choosing 316 stainless steel tubes, their mechanical and chemical properties, common applications, and how to select a reliable supplier. We’ll also introduce some of the leading 316 stainless steel tube supplier worldwide.

Understanding the key properties of 316 stainless steel tubes is crucial in ensuring they are suitable for your intended application. Here’s a closer look at both the mechanical and chemical properties of these tubes.

316 stainless steel is renowned for its excellent mechanical properties, which contribute to its widespread use in demanding industries. The primary mechanical characteristics of 316 stainless steel tubes include their yield strength, tensile strength, and elongation. Let’s break these down:

| Mechanical Property | Value |

|---|---|

| Yield Strength | 205 MPa (min) |

| Tensile Strength | 515-700 MPa |

| Elongation | 40% min in 50 mm |

| Hardness (HRB) | 95 max |

| Modulus of Elasticity | 193 GPa |

Yield Strength: This is the stress at which the material begins to deform permanently. For 316 stainless steel, the minimum yield strength is 205 MPa, indicating its resistance to deformation under heavy loads. This is a critical factor in high-pressure applications, such as oil and gas pipelines, where the tubes need to retain their shape and integrity under stress.

Tensile Strength: With a range between 515 MPa to 700 MPa, 316 stainless steel demonstrates its ability to withstand high tensile stress before breaking. This makes it an excellent material choice for structural applications where the material must endure tension without failure.

Elongation: This property measures how much the material can stretch before it fractures. With an elongation of 40% minimum in 50 mm, 316 stainless steel tubes can be bent or stretched to a certain degree, providing flexibility in manufacturing without compromising their structural integrity.

The corrosion resistance of 316 stainless steel is primarily attributed to its unique chemical composition. Below is a breakdown of the typical chemical components found in 316 stainless steel tubes:

| Element | Percentage |

|---|---|

| Chromium (Cr) | 16.0-18.0% |

| Nickel (Ni) | 10.0-14.0% |

| Molybdenum (Mo) | 2.0-3.0% |

| Carbon (C) | 0.08% max |

| Manganese (Mn) | 2.0% max |

| Silicon (Si) | 1.0% max |

| Phosphorus (P) | 0.045% max |

| Sulfur (S) | 0.03% max |

This combination of elements provides 316 stainless steel with excellent resistance to pitting, crevice corrosion, and oxidation, especially in chloride environments.

You may also like:

The Life Expectancy of 316 Stainless Steel

316 stainless steel tubes are used in various demanding industries due to their exceptional resistance to corrosion and strength. Here are some common applications:

When selecting a 316 stainless steel tube supplier, quality, reliability, and experience are the most important factors to consider. Here’s why:

The supplier should offer products that meet international standards such as ASTM, ISO, and EN certifications. This ensures that the tubes are manufactured according to global best practices and will perform as expected in your applications.

A supplier with years of experience in the stainless steel industry is more likely to offer high-quality products and services. Suppliers with a solid reputation often invest in advanced manufacturing technologies, which means they can provide more precise and durable products.

Cost is always a key consideration. A reliable supplier will offer competitive pricing without compromising product quality. Timely delivery is equally crucial, especially when you’re working on a time-sensitive project.

To make sure you choose the right 316 stainless steel tube supplier, consider the following factors:

A wide variety of tube sizes, finishes, and customization should be available. The supplier should be able to meet your specific requirements, whether you need standard sizes or bespoke solutions.

The supplier should be ISO 9001 certified, among other industry-specific certifications, to demonstrate their commitment to quality control.

The supplier’s ability to produce tubes with precise dimensions, wall thickness, and features (such as polished or annealed finishes) is important for meeting your specifications.

Suppliers should be able to provide accurate delivery timelines to ensure that your project does not experience unnecessary delays. Fast and reliable delivery is especially important for projects that involve tight schedules.

Choose a supplier that offers excellent customer service. This includes knowledgeable staff who can assist with inquiries, product selection, technical advice, and troubleshooting.

Here’s an expanded list of the top 20 316 stainless steel tube suppliers globally, known for their reputation, product quality, and global reach:

Allegro Stainless Steel

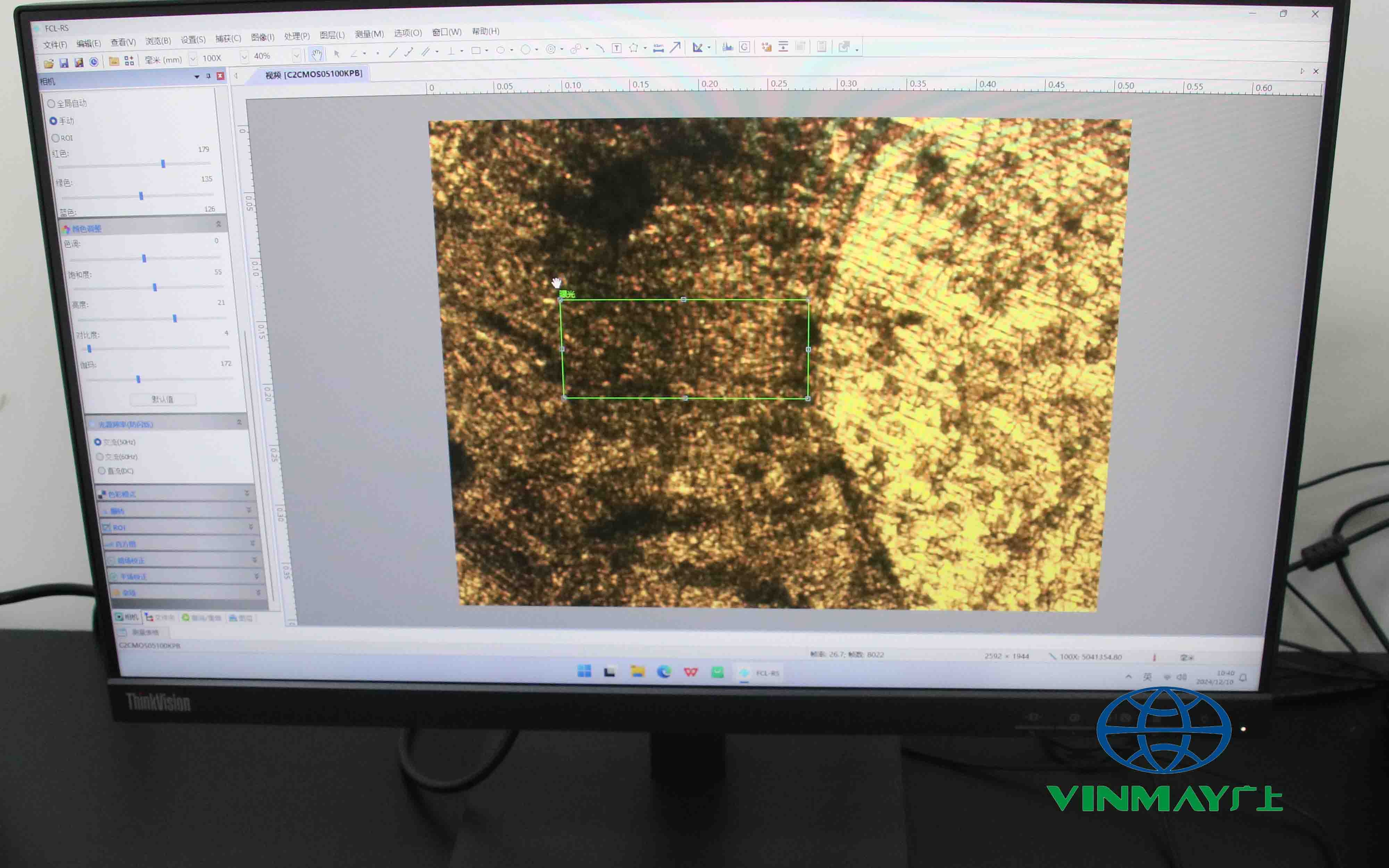

Foshan Vinmay Stainless Steel Co.,ltd

AK Steel

TISCO (Taiyuan Iron and Steel Group)

Shanghai Steel and Stainless Steel Co.ltd

Vallourec

Schoeller Bleckmann Edelstahlrohr GmbH

Thyssenkrupp Industrial Solutions

Severstal

Choosing the right 316 stainless steel tube supplier is crucial for the success of your project. The right supplier ensures you get high-quality tubes that meet international standards, delivered on time, and at a competitive price. A long-term relationship with a reliable supplier can provide consistency, cost savings, and peace of mind for your business.

If you're looking for premium 316 stainless steel tubes, contact Vinmay today. We offer high-quality products, on-time delivery, and expert support. Request a quote today to get started on your next project!