When it comes to stainless steel square tubing, navigating the cost considerations can be a complex task. With various types of stainless steel available and multiple factors affecting the cost, finding the right balance between quality and affordability becomes crucial.

In this discussion, we will explore the different types of stainless steel square tubing, the factors that can impact the cost, and how to compare prices from different suppliers. Additionally, we will delve into the impact of size and quantity on cost, and provide some valuable tips for purchasing budget-friendly stainless steel square tubing.

So, let's dive into the world of cost considerations and uncover the secrets to making informed decisions that meet your specific needs.

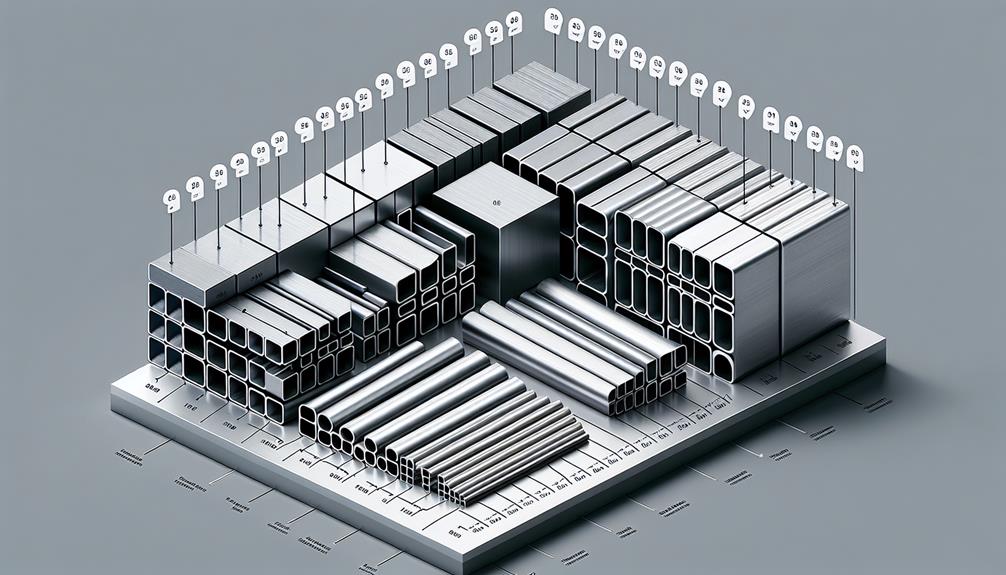

Stainless steel square tubing is a versatile and durable material used in various industries for its corrosion resistance and strength. What are the different types of stainless steel square tubing available in the market? Understanding the different types of stainless steel square tubing can help in choosing the right material for specific applications. Here are some common types:

Welded square tubing is a cost-effective choice, created by welding together individual pieces of stainless steel. This method provides strength and durability, making it suitable for both structural and ornamental purposes. Its availability in various sizes and thicknesses makes it a popular choice in construction and fabrication projects.

Recommended: Stainless Steel Welded Square Pipes vs. Round Pipe

Seamless square tubing is manufactured without any welding seams, ensuring a smoother interior surface. This type offers enhanced corrosion resistance and strength, making it ideal for high-pressure applications. It is commonly used in critical industries such as oil and gas, where reliability and durability are paramount.

Ornamental square tubing serves a dual purpose, offering both structural support and an aesthetic appeal. Designed for decorative applications, it often features intricate patterns or finishes. This type is prevalent in architectural projects and interior design, adding a touch of elegance to structures.

Polished stainless steel square tubing undergoes a polishing process to achieve a smooth and reflective surface. Beyond enhancing corrosion resistance, the polished finish provides a sleek appearance. This type is favored in applications where aesthetics play a crucial role, such as in architectural elements and high-end furniture.

Brushed square tubing is finished with a brushed texture, resulting in a matte appearance. This finish not only provides a unique visual appeal but is also resistant to fingerprints and smudges. It is commonly used in architectural projects, handrails, and furniture manufacturing.

Structural square tubing is engineered to meet specific structural requirements. Widely used in construction and engineering projects, it comes in various grades to fulfill strength and load-bearing specifications. This type provides reliable support and durability in diverse structural applications.

Heat-resistant square tubing is formulated to withstand high temperatures, making it suitable for applications involving exposure to extreme heat. Industries such as manufacturing and processing rely on this type for components in industrial ovens, furnaces, and heat exchangers.

Corrosion-resistant square tubing is designed to endure harsh environments and resist corrosion from chemicals and weathering. Widely used in marine applications, chemical processing plants, and industrial settings, this type ensures longevity and performance in challenging conditions.

Understanding the characteristics and applications of these types of stainless steel square tubing is essential for selecting the right material for a particular project. Whether it's for structural support, decorative elements, or withstanding challenging environments, choosing the appropriate type ensures optimal performance and longevity.

Read More: Applications of Stainless Steel Square Tubing Revealed

The cost of stainless steel square tubing is influenced by several factors.

One of the significant factors is the stainless steel grade. Different grades have varying levels of corrosion resistance and mechanical properties. Higher-grade stainless steel, such as 316 and 304, tend to be more expensive due to their superior performance in harsh environments.

Dimensional tolerances also affect the cost. Tighter tolerances require more precise manufacturing processes, leading to higher manufacturing process costs.

Achieving a desired surface finish, such as a polished or brushed appearance, may require additional processing steps, increasing the overall cost.

Formability is another factor that affects cost. Stainless steel square tubing with complex shapes or intricate designs may require specialized equipment and techniques during the manufacturing process, leading to higher costs.

Market demand fluctuations can also influence the cost. When demand is high and supply is limited, prices tend to increase. Conversely, during periods of low demand and excess supply, prices may decrease.

Achieving the optimal balance between quality and affordability is a critical consideration when selecting stainless steel square tubing. It is important to choose the right grade of stainless steel to ensure long-term durability while also keeping costs within budget. To help you make an informed decision, let's compare the quality and affordability of different stainless steel grades in the table below:

| Stainless Steel Grade | Quality | Affordability |

|---|---|---|

| 304 | High | Moderate |

| 316 | Excellent | High |

| 409 | Good | Low |

| 430 | Fair | Very low |

The table above highlights the trade-offs between quality and affordability. Grade 304 stainless steel offers high quality and moderate affordability, making it a popular choice for many applications. Grade 316 provides excellent quality but comes at a higher cost. On the other hand, Grade 409 offers good quality at a lower price point, while Grade 430 is more affordable but has fair quality.

When choosing the right grade, consider the specific requirements of your project and the level of durability needed. While it may be tempting to opt for a lower-priced grade, it is important to balance affordability with long-term durability. Investing in a higher-quality grade can result in cost savings in the long run by reducing maintenance and replacement costs.

Read more: Mastering 304 Stainless Steel Square Tubing

To make an informed decision when selecting stainless steel square tubing, it is essential to compare prices from different suppliers, considering the trade-offs between quality and affordability discussed earlier. Conducting a thorough cost analysis will help identify cost-effective options that meet your specific requirements.

When comparing prices from different suppliers, it is important to consider not only the upfront cost but also the long-term value. Cheaper options may seem appealing initially, but they may come with hidden costs such as poor quality, shorter lifespan, and higher maintenance expenses. On the other hand, higher-priced options may offer better quality and durability, leading to long-term savings.

To ensure accuracy in cost comparison, it is advisable to obtain detailed quotes from multiple suppliers. These quotes should include not just the cost of the stainless steel square tubing itself, but also any additional charges such as delivery fees, taxes, and customizations. By comparing these quotes side by side, you can identify the most cost-effective option that meets your project's requirements.

Furthermore, it is crucial to consider the reputation and reliability of the supplier. A supplier with a track record of delivering high-quality products and excellent customer service may be worth paying a slightly higher price for, as they are more likely to provide reliable and durable stainless steel square tubing.

Learn More: The Top-Rated Stainless Steel Square Tube Manufacturers

Understanding the cost implications of size and quantity is crucial when considering stainless steel square tubing for a project.

Pricing considerations play a significant role in determining the overall cost of the tubing. Generally, larger sizes of stainless steel square tubing tend to be more expensive than smaller sizes due to the higher material requirements and manufacturing complexity involved.

Additionally, the quantity of tubing required for a project can have a substantial impact on the overall cost. Suppliers often offer volume discounts, where the price per unit decreases as the quantity increases. Taking advantage of these discounts can result in significant cost savings.

It is important to carefully analyze the project requirements and determine the optimal size and quantity of stainless steel square tubing needed. By doing so, cost-saving strategies can be employed, such as purchasing in bulk or considering alternative sizes that meet the project's specifications while offering a more favorable price point.

Careful consideration of size and quantity can help control costs and ensure that the project remains within budget.

When aiming to minimize costs for stainless steel square tubing purchases, it is essential to carefully consider various strategies that can optimize budget allocation.

One effective approach is to negotiate with suppliers to secure the best possible prices. This can be achieved by researching and comparing prices from multiple suppliers, leveraging competition to your advantage. Additionally, purchasing in bulk quantities can often lead to discounted prices, as suppliers are more willing to offer lower rates for larger orders.

Another cost-saving tip is to explore alternative materials that can serve the same purpose as stainless steel square tubing. While stainless steel is known for its durability and corrosion resistance, there may be other materials that can meet your requirements at a lower cost. For instance, galvanized steel or aluminum square tubing can offer similar strength and durability, but at a reduced price point.

Furthermore, it is crucial to analyze the specific requirements of your project and determine if stainless steel square tubing is truly necessary. In some cases, alternative solutions such as using different structural elements or modifying the design can achieve the desired outcome at a lower cost. Conducting a thorough cost-benefit analysis can help you make informed decisions and optimize your budget allocation when purchasing stainless steel square tubing.

Specific dimensions for stainless steel square tubing vary depending on the manufacturer and application requirements. Common sizes range from 1/2 inch to 12 inches, with thicknesses ranging from 0.049 inches to 0.375 inches.

The grade of stainless steel has a significant impact on the cost of square tubing. Higher grades, such as 316 or 304, are typically more expensive due to their superior corrosion resistance and durability compared to lower grades.

The pricing of seamless versus welded stainless steel square tubing can vary due to factors such as production process, material quality, and market demand. It is important to consider these factors when navigating the cost considerations of stainless steel square tubing.

Surface finishes or coatings on stainless steel square tubing can add to the overall cost considerations. These additional costs are dependent on the type of finish or coating chosen, such as polished, brushed, or powder-coated, and the desired level of durability and aesthetic appeal.

The location of the supplier has a significant impact on the pricing of stainless steel square tubing. Global sourcing allows for cost savings through access to lower labor and production costs in different regions.

Blog Series:

In conclusion, navigating the cost considerations of stainless steel square tubing requires careful evaluation of factors such as the type and quality of the tubing, comparing prices from different suppliers, and understanding the impact of size and quantity on cost.

By finding the right balance between quality and affordability, purchasers can make budget-friendly decisions.

Interestingly, according to industry data, the average cost of stainless steel square tubing decreases by approximately 5% when purchasing in larger quantities.