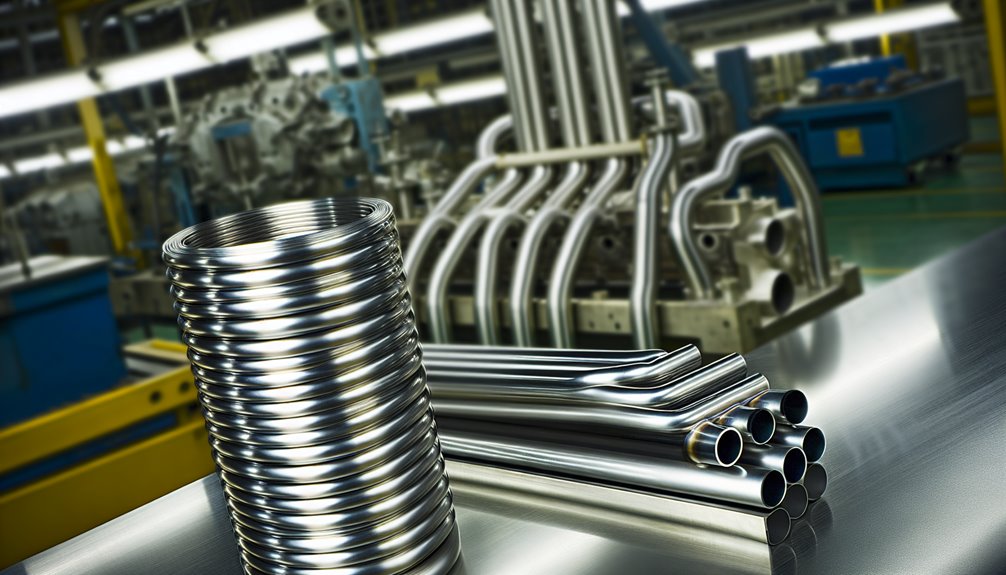

Automotive stainless steel tubing delivers high strength-to-weight ratios, corrosion resistance, and thermal stability for exhaust, fuel, brake, and hydraulic systems. Welded austenitic grades (304, 316/316L, 321) resist chloride attack, thermal cycling, and vibration; 409 offers cost-effective exhaust performance. Precision-formed tubes with controlled wall gauges and smooth IDs guarantee leak-tight, high-pressure conveyance and reduced turbulence. Applications include headers, catalytic converters, tailpipes, and structural members, lowering maintenance and improving longevity. Further details include grade selection, standards, and performance optimization.

Automotive components are exposed to harsh conditions that can quickly degrade inferior materials. Stainless steel tubing provides clear advantages:

These qualities make stainless steel tubing an ideal choice for OEMs, performance part manufacturers, and global automotive suppliers.

Automotive applications of stainless steel tubing concentrate on exhaust systems, fuel and hydraulic lines, structural members, and select engine components where corrosion resistance, high-temperature strength, and formability are critical.

Grades such as 304/304L/316L, produced to ASTM A249/A269/A554 or comparable EN standards, enable thin-wall fabrication with consistent weld integrity and pressure containment.

Data from OEM adoption shows stainless maintains performance under thermal cycling (>700°C in exhaust) and fluid exposure (fuel, brake, and hydraulic media), reducing failure rates and lifecycle cost versus coated carbon steel.

Additionally, when applications demand superior chloride resistance and higher durability, 316 stainless tubes produced to ASTM A312/A269 offer enhanced performance in harsh underbody and coastal environments.

Heat, corrosion, and vibration define the operating envelope of exhaust systems, making welded stainless steel tubing the material of record for headers, mufflers, catalytic converters, and tailpipes.

Optimized wall gauges and controlled weld integrity preserve exhaust efficiency, pressure-wave tuning, and noise reduction. Austenitic grades (304/304L/316L) resist chloride-rich condensates and thermal cycling, securing durability and surface finish.

Tailpipe and canister geometries maintain backpressure targets and minimize lifecycle maintenance.

For components exposed to salt spray and road de-icing chemicals, choosing 316 stainless steel improves pitting and crevice corrosion resistance and extends service life.

Precision-formed welded tubing in austenitic grades (304/304L/316L) delivers leak-tight, high-pressure conveyance for fuel injection, hydraulic brake, and transmission fluid circuits.

Tight ovality, controlled wall thickness, and smooth ID minimize turbulence, enhancing metering accuracy and fuel efficiency. Superior pressure resistance and corrosion stability sustain pulse loads, brake line integrity, and thermal cycling.

Consistent weld beads and NDT-verified seams guarantee durable sealing, reduced maintenance, and predictable system response under demanding duty cycles.

For harsh environments and chloride exposure, selecting 316/316L with molybdenum improves resistance to pitting and crevice corrosion as outlined in ASTM A270.

Beyond fluid conveyance, the same austenitic grades (304/304L/316L) in welded stainless steel tubing provide high specific strength, stiffness retention at elevated temperatures, and stable energy absorption for load-bearing structures.

In racing and specialty vehicles, tubes are specified for roll cages, chassis supports, and safety reinforcements to maximize structural integrity and weight reduction.

Controlled weld quality, ovality, and surface finish improve fatigue resistance, crush performance, and dimensional stability under multi‑axis loading.

These tubes also leverage the superior corrosion resistance and formability of 304 stainless steel, supporting long-term durability and reliable weldability in demanding automotive environments.

Although engine bays impose combined thermal, vibrational, and corrosive loads, stainless steel tubing—particularly austenitic grades 304/304L/316L and stabilized 321—delivers reliable performance for turbocharger connections, high-performance exhaust manifolds, and engine-mounted fluid or air systems.

It safeguards engine performance and thermal efficiency through creep resistance, oxidation resistance, and weld integrity.

1) 321 for elevated-temperature turbo links

2) 316L for chloride-laden coolant circuits

3) 304/304L for air, vacuum, and sensor lines

Additionally, 316/316L rectangular tubes offer superior corrosion resistance and excellent weldability, with customizable surface finishes that enhance durability in harsh automotive environments.

Different areas of a vehicle require tubing that can handle unique conditions such as heat, pressure, and exposure to corrosive environments. Choosing the right stainless steel grade ensures long-term performance and cost efficiency. The most common grades used in the automotive industry include:

By offering multiple stainless steel grades, Vinmay ensures automotive manufacturers can select the most suitable tubing solution for each application — whether it’s balancing cost efficiency, corrosion resistance, or high-temperature durability.

Vinmay has earned global recognition for supplying high-quality stainless steel welded tubes designed for demanding industries, including the automotive sector. Here’s what sets us apart:

With a strong reputation for reliability and innovation, Vinmay is the trusted partner for automotive stainless steel tubing solutions.

Contact Vinmay today to discuss your requirements or request a customized quote.

For exhaust header assemblies, stainless steel tubing must sustain continuous gas temperatures above 800°C, tolerate condensate- and sulfur-bearing corrosion, and maintain tight ovality through multi‑axis mandrel bends and fusion welds.

Vinmay’s 304 and 321 welded tubes deliver thermal resistance, oxidation stability, and weld integrity, enabling predictable exhaust performance.

Switching from mild steel extends service life, cuts maintenance, and preserves flow geometry, improving efficiency under cyclic load and vibration.

Selecting 316L in chloride-rich road environments can further enhance corrosion resistance due to its molybdenum content and reduced sensitization risk, aligning with ASTM A270 sanitary and quality expectations in critical applications.

They comply with certification standards ASTM A249/A269/A270/A554 and EN10217-7/EN10357/DIN11850. Testing methods include hydrostatic, eddy current, dimensional, surface finish, chemical composition, and mechanical tensile/flattening/flaring. Coincidentally, all grades 201/304/304L/316L align, enabling traceable QA documentation and controlled delivery.

Yes. They support custom tube applications with OEM design flexibility: cut-to-length precision, surface finishes (brushed, mirror, matte), and color customization. Grades 201/304/304L/316L available; tolerances per ASTM/EN standards; lead time up to 15 days.

Typical lead times are 15 days; minimum order requirements vary by grade and dimension. Lead time considerations depend on customization and standards. Importantly, 87% of delays stem from specification changes—control parameters early to maintain schedule certainty.

They manage global logistics via one-stop services: route optimization, INCOTERMS alignment, customs brokerage, and compliance with shipping regulations. Integrated supply chain tracking, HS code accuracy, documentation audits, and pre-clearance minimize delays. Multi-modal options and flexible payment terms support controlled delivery.

Yes—free samples and technical support are available. Scarcity meets control: sample availability is immediate; prototyping assistance includes material selection, standards compliance (ASTM/EN/DIN), dimensional verification, and process parameters, enabling rapid iteration, measurable tolerances, and risk-reduced validation for decision-makers.

In evaluating the theory that stainless steel tubing is indispensable to next-generation vehicles, evidence is persuasive. Quantified gains 10x corrosion life versus coated carbon steel, stable properties to ~800°C, and ±0.05 mm tolerance control in welded tubes—translate to lighter exhausts, leak-tight fuel/brake lines, and durable EGR/cooling circuits. Grades 304/304L/316L balance formability and chloride resistance, while robotic-weld joinability guarantees repeatability. As EVs and hybrids demand thermally and chemically robust circuits, data suggest stainless tubing isn’t optional—it’s the reliability baseline.