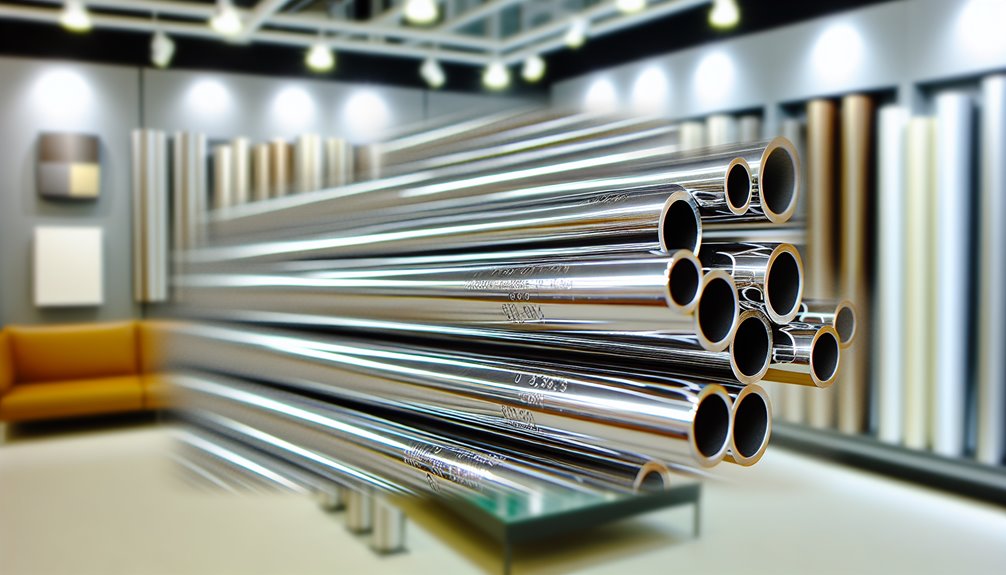

Stainless steel pipe for furniture offers a unique combination of strength, durability, and aesthetic appeal, making it a versatile choice for various applications. Its high resistance to corrosion and rust guarantees longevity, while its sleek surface contributes to modern design. Precision-engineered dimensions and robust manufacturing techniques provide structural integrity and support for heavy loads. Interested parties may find themselves intrigued by how these properties can transform innovative design projects.

A furniture-grade stainless steel pipe is a type of stainless tubing specifically manufactured to meet the strength, surface, and dimensional requirements of furniture production. Unlike industrial or plumbing pipes, these tubes are designed for applications where appearance, precision, and weld quality are just as important as structural performance.

Furniture pipes are typically made from austenitic stainless steel grades, such as 304 and 316L, known for their excellent formability, corrosion resistance, and smooth finish.

In addition to material grade, surface finishing plays a key role in creating the right visual and tactile effect. Common finishes include brushed, mirror-polished, and satin, each suited for different design styles. Dimensional accuracy — including consistent wall thickness, roundness, and smooth weld seams — ensures that the pipe integrates perfectly into furniture assemblies and maintains a refined appearance over time.

Choosing the correct furniture-grade stainless steel pipe helps manufacturers achieve both aesthetic quality and long-term performance, reducing rework and ensuring every product reflects precision craftsmanship.

Engineered for ideal performance, stainless steel pipe has become a preferred material in modern furniture design due to its unparalleled durability and aesthetic qualities.

Its stainless steel advantages include a robust resistance to rust, corrosion, and staining, guaranteeing longevity and minimal maintenance. The precision of pipe fabrication allows for high structural integrity, accommodating heavy loads without compromising form.

Key benefits include:

These attributes make stainless steel pipe a superior choice for furniture that demands both form and function.

Selecting the right stainless steel pipe for furniture is essential for achieving the perfect balance between strength, appearance, and cost efficiency. The key factors to consider are pipe grade, diameter, wall thickness, and surface finish — each influencing performance and fabrication outcomes.

Choosing the right grade ensures that your furniture maintains both its appearance and integrity under expected environmental conditions.

The outer diameter (OD) and wall thickness determine the load-bearing capacity and stability of furniture frames.

Precision in these measurements ensures proper fit during assembly and prevents deflection or bending under load.

A polished or brushed surface not only enhances visual appeal but also improves corrosion resistance. Indoor furniture often uses a satin or hairline finish for a refined look, while outdoor products may benefit from mirror or PVD-coated surfaces for added protection.

In short, the best furniture-grade stainless steel pipe combines the right grade, dimensions, and finish for the intended design and usage — ensuring structural safety, production efficiency, and a consistent aesthetic finish.

Designing furniture with stainless steel pipes requires precision in both engineering and aesthetics. From the frame structure to joint connections, each detail affects the stability, longevity, and visual quality of the finished piece. The following design guidelines help ensure that stainless steel furniture achieves the right balance between strength and style.

The geometry of the frame determines how loads are distributed. For furniture such as chairs, benches, or shelving, use tubular arrangements that minimize bending moments and allow forces to transfer along the pipe’s axis. Round or square tubes with adequate wall thickness provide strong yet lightweight designs.

Welded joints should be smooth, continuous, and free from porosity. TIG (Tungsten Inert Gas) welding is typically preferred for stainless steel pipe for furniture, as it delivers clean, precise seams with minimal distortion. For modular or knock-down furniture, mechanical joints using inserts or clamps can allow easier assembly without compromising aesthetics.

High-quality furniture requires tight tolerances in pipe diameter, straightness, and edge alignment. Inaccurate cuts or misalignment can lead to visible gaps or uneven surfaces, especially in mirror-polished designs. Using CNC cutting and automated bending machines helps maintain precision.

When designing seating, tables, or fixtures, the pipe diameter should also consider comfort and usability. For example, a 32 mm round tube offers a good balance between grip and structural rigidity for chair arms or handrails.

A polished or brushed finish elevates the product’s visual quality, while radius bends and smooth transitions reduce stress concentrations. Always plan for the final finish during the design stage, as polishing after assembly can be more labor-intensive.

By applying these principles, manufacturers can make the most of stainless steel furniture tubing—producing designs that are visually refined, structurally strong, and built for long-term performance. steel furniture not only performs well but also meets desired aesthetic and functional standards.

The surface finish and corrosion protection of stainless steel pipe for furniture play a crucial role in both appearance and long-term durability. Choosing the right combination ensures the furniture maintains its aesthetic appeal while withstanding environmental stresses.

Routine care is simple but essential. Wiping down surfaces with a soft cloth and mild cleaner helps prevent staining and surface oxidation. For outdoor installations, periodic inspection for scratches or localized corrosion ensures the furniture maintains both its appearance and structural integrity.

By carefully selecting finishes and protective measures, furniture designers and manufacturers can ensure that stainless steel pipe furniture remains visually appealing and durable for years, reducing maintenance costs and preserving brand quality.

When selecting materials for furniture production, understanding the cost implications of stainless steel pipe for furniture is essential. While stainless steel may have a higher initial material cost than mild steel, its long-term value often justifies the investment.

When considering total lifecycle cost — material, fabrication, maintenance, and replacement — stainless steel pipe furniture often provides a better ROI, particularly for high-use or high-visibility applications such as commercial seating, outdoor benches, and high-end architectural pieces.

By evaluating both initial investment and long-term performance, manufacturers can make informed decisions, ensuring that the choice of stainless steel pipes supports both quality and cost-efficiency in furniture production.

Even experienced furniture manufacturers know that not all stainless steel pipes are created equal. Beyond material grade and diameter, subtle differences in production and handling can significantly affect final performance:

At Vinmay, every pipe undergoes rigorous dimensional checks, chemical analysis, and surface inspection before shipping. This ensures that our stainless steel pipes integrate seamlessly into production, maintain structural integrity, and preserve the desired finish — batch after batch.

For projects where precision, durability, and aesthetics cannot be compromised, Vinmay provides the reliability and technical support that experienced manufacturers demand.

Stainless steel pipe for furniture is widely used across multiple applications where durability, corrosion resistance, and aesthetic appeal are essential. Its versatility makes it suitable for both functional and decorative purposes:

1. Office and Commercial Furniture

Stainless steel pipes are ideal for creating desk frames, partition supports, shelving, and seating. Their strength and precision ensure long-lasting stability while allowing sleek, minimalistic designs that fit modern office aesthetics.

2. Residential Furniture

From bed frames and tables to storage units, stainless steel pipes provide a clean, contemporary look. The material’s corrosion resistance and smooth finishes make it suitable for kitchens, bathrooms, and living spaces where durability and hygiene are important.

3. Outdoor and Public Spaces

Grade 316L stainless steel pipes are particularly suitable for outdoor furniture such as benches, tables, and handrails. Their natural resistance to moisture and environmental exposure ensures long-term performance with minimal maintenance.

4. Retail and Hospitality Fixtures

Stainless steel pipe furniture supports high loads in environments like restaurants, hotels, and retail displays. The polished or brushed surfaces maintain a professional appearance, withstand frequent cleaning, and complement other design elements.

Stainless steel pipes, immortal in their durability, can indeed be recycled, integrating seamlessly into recycling processes. Embracing sustainable practices, their material properties allow for efficient reuse, maintaining structural integrity, and reducing environmental impact through precise recycling methodologies.

The environmental impacts of using stainless steel in furniture include energy-intensive manufacturing processes and resource extraction. However, sustainability practices, such as recycling and efficient material use, mitigate these effects, enhancing durability, minimizing waste, and promoting long-term material efficiency.

Stainless steel furniture generally weighs more than wood furniture due to higher material density. This weight comparison highlights structural analysis: stainless steel's density offers enhanced sturdiness and durability, while wood provides lighter, yet less robust, options.

In 2024, stainless steel furniture design trends emphasize minimalism and geometric shapes, with color trends favoring metallic finishes and matte black. The material's precision and structural integrity align with a growing preference for sleek, modern aesthetics.

Stainless steel pipe furniture aligns seamlessly with minimalist designs, marrying sleek aesthetics with structural integrity. Its clean lines and reflective surfaces underscore modern minimalism, providing durable, low-maintenance solutions that emphasize functionality and restrained elegance, suitable for controlled environments.

Choosing Vinmay ensures access to high-quality stainless steel pipes and fittings backed by extensive industry expertise. With a broad product range — from welded stainless steel pipes to specialized handrail components — Vinmay supports diverse applications in construction, furniture, and chemical industries.

Vinmay’s competitive advantages include:

With a commitment to superior customer support, including online inspections and dedicated logistics services, Vinmay delivers not only products but also peace of mind.

Partner with Vinmay today to source stainless steel pipes that combine durability, precision, and design flexibility — and take your furniture and construction projects to the next level.